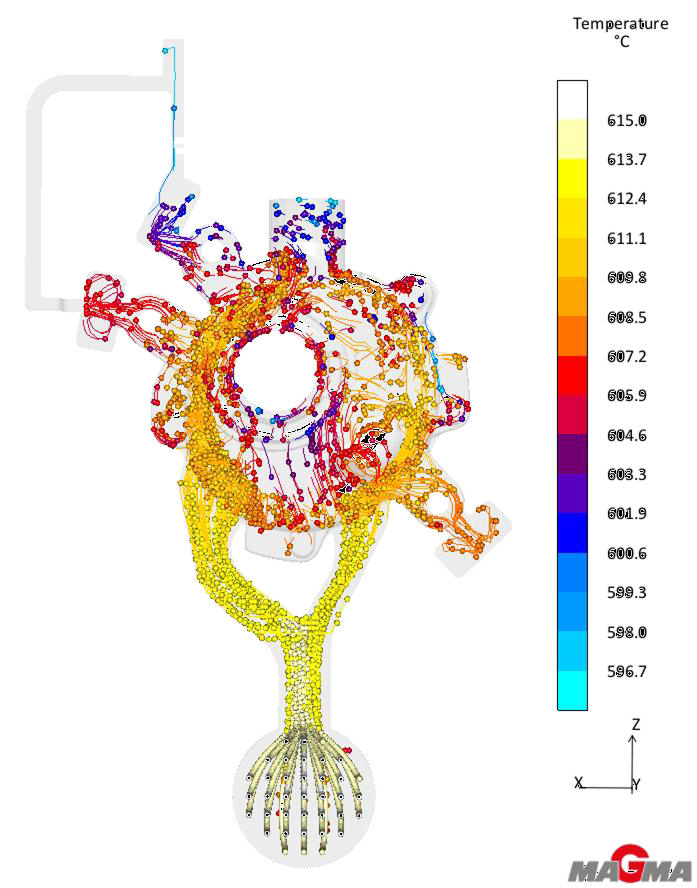

1: the feeding process and the geometric characteristics of the tube in the chamber.Ĭonsidering the available mechanical properties (PQ2 diagram), the exhaust conditions in the die casting mold, and the complete thermal balance, which is essential for the quality of the castings, an assessment can be made at the early stages of process and die design. It can optimize feeding parameters, material stabilization time, punch speed and speed switching point.įig. With these characteristics, MAGMASOFT 5.4 can study the feeding process and geometric characteristics of the tubing (Fig. The new solver can simultaneously calculate different fluid models (such as those passing through the cooling tube during casting filling) and support flexible boundary conditions (punch movement, extrusion).

MAGMASOFT 5 FREE

The new algorithm considers the free surface, viscosity and entrainment prediction of liquid metal during the filling process of high pressure casting, so as to obtain more accurate results. With the help of innovative TAG-mesh generation (true adaptive geometry), MAGMASOFT < 5.4 allows for flexible local meshing of geometries.

MAGMASOFT 5 SOFTWARE

The major advances in the new version of the software are that it provides tremendous support for parts design, mold development and process planning for high-pressure castings.

To this end, the new version has been fully improved and improved, so that users in the use of the simulation software for independent design become more efficient. By specifying quantitative objectives and key production variables in the software, it is easy to realize synchronous optimization of casting design, mold design and robust process design during the development of the whole process.

MAGMASOFT 5 FULL

With the help of the latest version of MAGMA Giessereitechnology, Aachen, Germany, MAGMASOFT < 5.4, the world's leading supplier of casting process optimization software provides the latest fully functional tools for casting design, mold design and robust production process optimization.īy incorporating the megacode six-step method and independent design into the software, users can make full use of virtual experiments to ensure reasonable decision-making, and analyze the root causes. For further information how we process your personal data, please follow this link Privacy Policy.MAGMASOFT 5.4 independent design casting process optimization software starts globally synchronously It will not be passed on to third parties.

MAGMASOFT 5 DOWNLOAD

When downloading the PDF, please leave your contact data (you will receive the download link by e-mail) and thus agree to the processing and storage of it by MAGMA casting technology GmbH in Aachen.

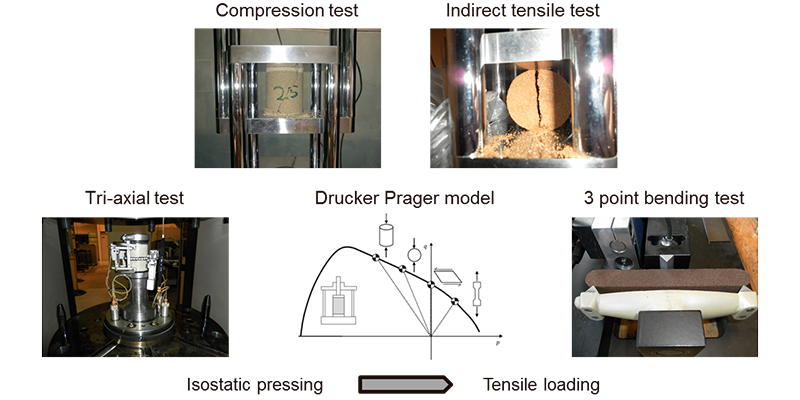

Thermal loading including buoyancy during filling and early stage solidification.Mechanical behavior of different sand and binder systems.

Prediction of core deformation as a function of

0 kommentar(er)

0 kommentar(er)